News

Evolution Free Zone: Leading the Era of Free Trade Zones 5.0

5 de January de 2026Five Manufacturing Trends Shaping 2026

February 2026. As 2026 begins, the manufacturing industry is undergoing a profound transformation, focused on elevating operational efficiency, resilience, and long-term competitiveness. The convergence of artificial intelligence, advanced automation, material innovation, and sustainability is redefining manufacturing as an interconnected ecosystem.

These key developments are already shaping business decisions, site selection strategies, and workforce planning across industries. Below are five trends that industry leaders expect will redefine manufacturing in 2026.

1. AI and the Rise of Autonomous Operations

Artificial Intelligence is becoming the operating system of manufacturing in 2026. Beyond analytics and decision support, industrial AI—particularly AI agents— will actively manage factory operations in real time.

These systems will coordinate machinery, inventory, maintenance schedules, and human resources, aiming to prevent bottlenecks, reduce downtime, and autonomously optimize output. As adoption accelerates, manufacturers will move closer to fully self-optimizing smart factories.

As manufacturing advances toward more intelligent and autonomous models, the environment in which it operates must adapt accordingly. Infrastructure, digital readiness, and operational flexibility are now critical enablers of AI-driven manufacturing.

Business environments that support AI-driven manufacturing operations—through infrastructure, digital readiness and operational flexibility—are becoming increasingly relevant. Evolution Free Zone reflects this shift, particularly for industries such as MedTech, Smart Manufacturing, and Semiconductors. Our High-Tech Business Park has been purpose-built to support next-generation operations, offering the infrastructure, flexibility and digital capabilities required to deploy intelligent manufacturing solutions.

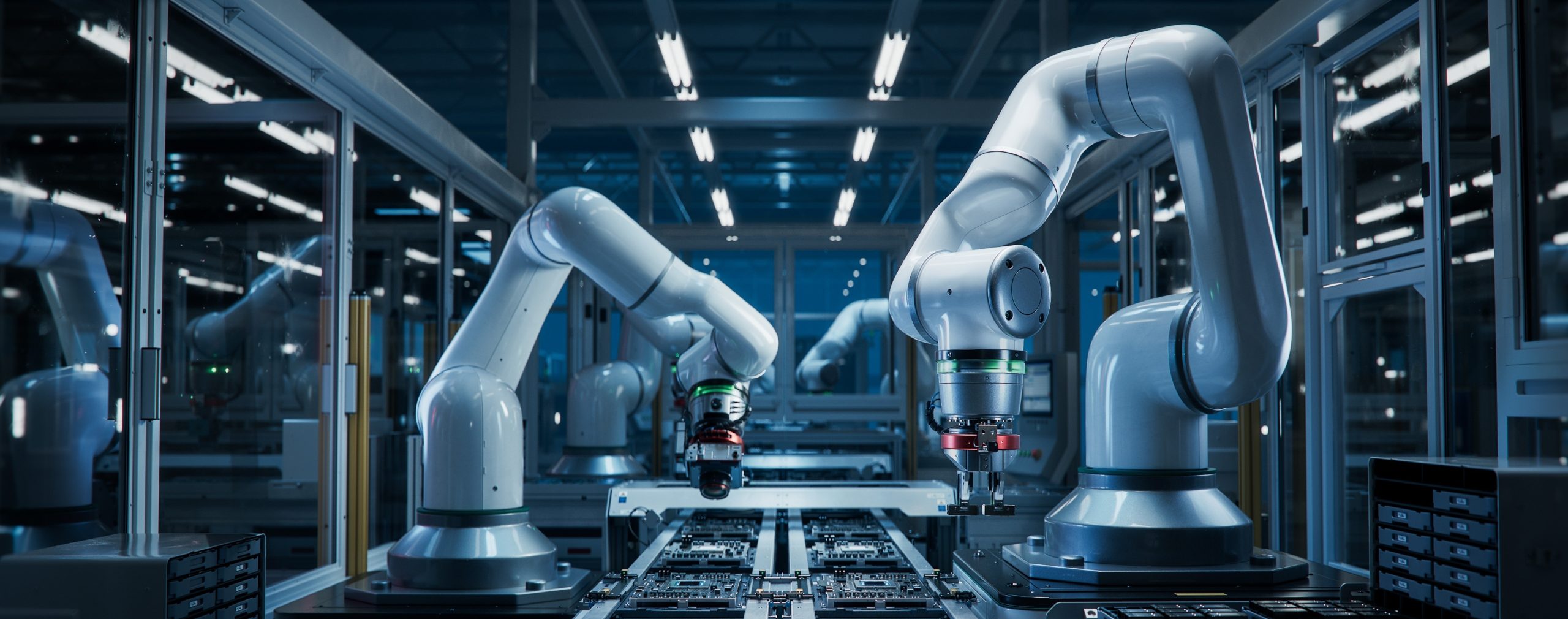

2. Robotics as a Strategic Driver for Manufacturing Competitiveness

Next-generation industrial robots are operating with greater autonomy, precision and intelligence, enabling manufacturers to ensure consistent quality across high-value production processes, serving as a structural response to workforce needs, quality requirements, and rising complexity in manufacturing.

As a result, competitiveness will progressively depend on smart manufacturing facilities capable of supporting robotics-intensive operations through reliable power infrastructure, advanced connectivity, and flexible layouts that evolve alongside automation technologies.

3. Resilient Supply Chains

Supply chains in 2026 will be proactive, adaptive, and autonomous. Enabled by AI, digital twins and industrial IoT, manufacturers are transitioning toward intelligent supply networks that respond in real time to disruption.

These systems dynamically adjust sourcing, inventory and production based on sensor data, supplier availability and global events—making site selection more strategic than ever.

To operate effectively within dynamic supply networks, manufacturers require locations that support speed, visibility and operational continuity. Evolution Free Zone contributes to this shift by providing a business environment designed to facilitate data-enabled operations, real-time monitoring and seamless connectivity.

These capabilities are reinforced by our location in the heart of the Americas. Situated in the Western Region of Alajuela, Evolution Free Zone is the first Business Park with direct access to National Route 1, enabling efficient connections to the country’s main highways and ports, and just 15 minutes from Juan Santamaría International Airport—supporting time-sensitive manufacturing and cross-border supply chain operations.

4. Sustainability Moves from Commitment to Execution

Sustainability has become an operational imperative. Technological innovation across energy optimization, digital efficiency and sustainable materials is enabling tangible progress toward decarbonization.

By 2026, sustainability will be embedded into core manufacturing operations, directly influencing site selection, facility design, and long-term business decisions. For manufacturers, sustainability performance has a growing impact on regulatory compliance, customer expectations, and access to capital.

At Evolution Free Zone, sustainability is integrated across every dimension of operations. From smart infrastructure to strategic community engagement, our High-Tech Business Park is cultivating a purpose-driven business ecosystem designed for long-term value creation. Key initiatives include:

- An on-site solar farm that generates renewable energy to support sustainable operations in common areas.

- 100% of irrigation for green areas using treated and reused water.

- Smart lighting systems are deployed across all our world-class infrastructure.

- Class A+ facilities tailored to meet the specific operational needs of industries such as Life Sciences, Smart Manufacturing and Semiconductors.

- Strategic alliances with the 10 local governments of the Western Region.

- Reforestation initiatives with more than 3,000 native trees planted to date.

- Partnerships with public and private educational institutions to develop local talent with the skills needed for advanced manufacturing industries.

5. Industry 5.0

Industry 5.0 will gain strategic relevance in 2026 as manufacturers seek to balance advanced automation with human expertise. This approach ensures that technology enhances—rather than replaces—the workforce.

Collaborative robots, intuitive human-machine interfaces and continuous upskilling programs will enable humans and machines to operate together safely and efficiently, while workforce well-being and environmental responsibility remain central to industrial progress.

As a Free Trade Zone 5.0, Evolution Free Zone provides a strategic business environment for global companies aiming to operate smarter, grow responsibly, and succeed.